HD Hyundai is accelerating the digital transformation of its shipyards by integrating advanced artificial intelligence (AI) and digital twin technology. To address rising ship demand and labor shortages, the company is collaborating with global tech firms such as Palantir Technologies and Siemens to enhance automation and operational efficiency.

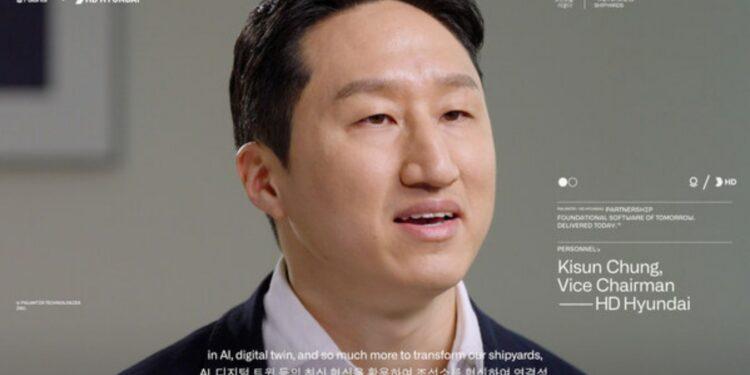

Executive Vice Chairman Chung Ki-sun has reiterated HD Hyundai’s commitment to developing a highly automated shipyard with minimal human intervention. As part of this effort, the company is strengthening partnerships with leading technology providers, including Palantir, known for its AI-driven decision-making software, and Siemens, a global industrial solutions leader.

As part of its Future of Shipyard (FOS) initiative, HD Hyundai is integrating Palantir Technologies’ AI-driven Foundry platform to optimize shipyard operations. A recently released video by Palantir highlights how collaboration enhances automation, improves decision-making, and reduces manual labor. The FOS project, launched in 2021, is structured into three phases, with the ultimate goal of creating an intelligent, autonomous shipyard by 2030.

HD Hyundai expects the implementation of AI, big data analytics, robotics, and automation to significantly enhance productivity. Upon full deployment, the company projects a 30% increase in efficiency and a similar reduction in shipbuilding time.

In addition to AI-driven automation, HD Hyundai is advancing its digital twin capabilities through partnerships with Siemens and Nvidia. By creating virtual models of shipyards, the company enables real-time monitoring and predictive optimization of shipbuilding processes. Nvidia CEO Jensen Huang showcased this collaboration at Nvidia GTC 2024, emphasizing the role of advanced graphics technology in improving precision and minimizing inefficiencies.

The digital transformation extends beyond shipyards as HD Hyundai continues to strengthen its global research and development footprint. The company has established R&D centers in Germany and India to drive AI, automation, and marine mobility solutions innovation. These efforts position HD Hyundai as a leader in next-generation shipbuilding technology.

With ship demand increasing and labor shortages persisting, HD Hyundai’s collaboration with global tech firms highlights its strategic shift toward smart manufacturing. By embracing AI, digital twins, and automation, the company is improving operational efficiency and setting new industry standards for the future of shipbuilding.

HD Hyundai is integrating Palantir’s Foundry platform to enhance operational efficiency and cost management in its shipyards. The system gathers real-time data from hull assembly plants, detecting resource imbalances to optimize workload distribution. Additionally, Foundry’s simulation tools allow virtual testing of different ship engine configurations, helping engineers identify the most effective assembly strategies.

Executive Vice Chairman Chung Ki-sun has consistently emphasized the company’s commitment to digital transformation, marine mobility innovation, and sustainability. He has outlined a vision centered on electrification, autonomous operations, and eco-friendly technologies. To drive this innovation, HD Hyundai has established global R&D centers, including its India Technology Center in Pune and its European R&D Center in Germany, ensuring continuous collaboration with leading research institutions.