The KRW 930 billion facility will produce next-generation hydrogen fuel cells and electrolyzers, positioning Hyundai and South Korea at the center of the global hydrogen transition.

Hyundai Motor Company has begun construction of a large-scale hydrogen fuel cell production facility in Ulsan, South Korea, marking a milestone in the company’s transition from traditional engines to clean energy systems.

The ceremony, held this week, was attended by Hyundai Motor Group Vice Chair Jaehoon Chang, Minister Sungwhan Kim of the Ministry of Climate, Energy and Environment, and other senior government officials. International hydrogen advocates also joined the ceremony, including Ivana Jemelkova, CEO of the Hydrogen Council, who was visiting Korea for the upcoming 2025 APEC CEO Summit in Gyeongju.

Repurposing a Legacy Site for Future Mobility

The new plant will cover 43,000 square meters on the grounds of a former internal combustion engine transmission plant — a symbolic gesture of Hyundai’s shift away from fossil-fuel-based technologies.

Once completed in 2027, the facility will be capable of producing 30,000 hydrogen fuel cell units annually. It will operate under Hyundai’s HTWO brand, which represents the company’s hydrogen and fuel cell business under the theme “Hydrogen for Humanity.”

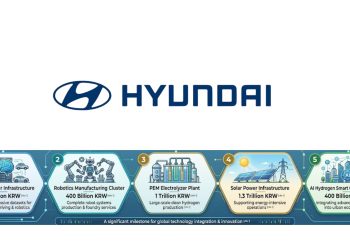

The total investment of KRW 930 billion (approximately USD 660 million) will fund the production of next-generation fuel cells and electrolyzers for multiple applications, including passenger vehicles, commercial trucks, construction equipment, and marine vessels.

“This plant embodies Hyundai Motor Group’s strategic commitment to advancing the hydrogen society transition,” Vice Chair Chang said during his address. “It will serve as a critical foundation for securing economic growth and establishing Korea’s leadership in the global hydrogen industry.”

Focus on Next-Generation Fuel Cell and Electrolyzer Technology

The facility will focus on developing two key technologies:

- Next-generation hydrogen fuel cells, designed to deliver higher power output, longer durability, and improved cost efficiency.

- Polymer Electrolyte Membrane (PEM) electrolyzers, which produce hydrogen from water without carbon emissions.

Hyundai said this will be the first large-scale production of PEM electrolyzers in Korea, a crucial step toward achieving net-zero energy goals.

The company has already developed a 1 MW containerized electrolyzer system that produces 300 kilograms of hydrogen daily. A larger 5 MW project is currently under construction in Jeju, intended to support local green hydrogen production and ecosystem development.

Building a Smarter, Safer Manufacturing Platform

Hyundai plans to operate the new plant as an advanced manufacturing platform, integrating robotics, automation, and safety monitoring systems.

According to the company, robotic systems will handle repetitive or heavy tasks to reduce physical strain on workers, while real-time sensors will detect safety risks and prevent workplace accidents.

Strengthening the Hydrogen Value Chain

The fuel cells produced at the Ulsan facility will support a wide range of applications across mobility, logistics, and power generation. Hyundai Motor Group is also building a full hydrogen value chain — from production and storage to transport and utilization — in cooperation with domestic and international partners.

The company’s ongoing collaborations with governments, research institutions, and private enterprises are intended to make hydrogen an accessible and commercially viable energy source across multiple sectors.

At the ceremony, Hyundai Motor and KGM Commercial, a Korean bus manufacturer, signed a Memorandum of Understanding (MoU) for hydrogen fuel cell supply — demonstrating how the new plant could accelerate the adoption of hydrogen-powered public transport in Korea.

National and Global Implications

The groundbreaking aligns with South Korea’s national strategy to become one of the top three hydrogen economies globally by 2030. The government sees hydrogen as essential for decarbonizing heavy industries and transportation — sectors that together account for a large portion of national emissions.

Hyundai’s investment also strengthens Korea’s role in the global hydrogen market, where competition is rising among Japan, Europe, and the United States.

Experts note that by integrating fuel cell production with electrolyzer manufacturing, Hyundai can reduce supply chain dependencies and lower the overall cost of hydrogen energy systems.

Looking Ahead: A Symbol of Industrial Transition

Hyundai’s new Ulsan facility is more than a production site — it symbolizes the company’s shift from an internal combustion legacy to a clean energy future.

The factory will scale up production in line with global demand for hydrogen technologies, contributing to both Korea’s carbon neutrality goals and the international push for sustainable industrial transformation.

By merging industrial expertise, government support, and technological innovation, Hyundai Motor aims to transform Ulsan — once the hub of traditional automotive manufacturing — into a center for green mobility and hydrogen innovation.