Hyundai Motor Group and Kia Motors Corporation on Wednesday launches a new design evaluation system powered with virtual reality (VR) to respond to the rapidly changing automotive market.

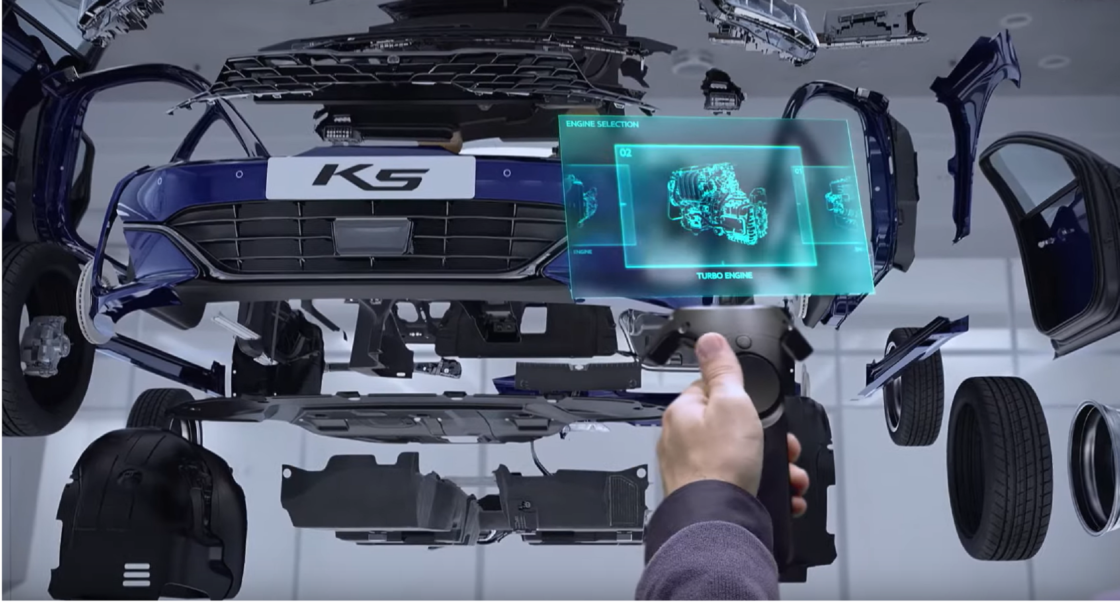

The car manufacturer’s new evaluation system improves efficiency and design quality. Utilizing VR headset technology allows for 20 individuals to participate in the design development simultaneously. The VR experience also includes design quality assessments and verification processes.

The technology uses 36 motion tracking sensors to detect and track the movement and locations of all users. The VR headsets enable engineers and designers to partake in the developmental simulations virtually.

Engineers can use the VR design quality verification processes to fast-track the development of safety technologies, testing vehicles in different simulated environments such as urban roads, tunnels, hill, highways, and low-light conditions.

Three-dimensional Computer-Aided Design (CAD) helps Hyundai Motor and its affiliate Kia Motors to collect data from every step of the vehicle development process and assess the quality of each design in virtual environments.

The new design evaluation system simulates exterior and interior design features such as lighting, material, colors, and also virtual environments.

The VR technology came after the car manufacturer’s KRW 15 billion ($12.8 million) investment in Namyang Research and Development (R&D) Center.

The new technology comes after the automaker an announcement in March it would invest KRW 15 billion ($12.8 million) in the Namyang Research and Development (R&D) Center.

The company anticipates decreasing vehicle development times and annual development costs by 20 and 15 percent, respectively, employing the virtual development processes throughout the R&D.

The carmakers also expect an increase in profitability from the use of VR technology. The new system will also establish a cycle of increasing Hyundai and Kia R&D reinvestment.

Albert Biermann, head of R&D division at Hyundai Motor Group, said in a press conference, “The virtual development process is a necessary step for responding quickly and reacting with agility to the needs of customers and paradigm shifts within the automotive industry.”

He added, “Through reinforced virtual processes, we will enhance quality and profitability, ultimately increasing investment in R&D to secure competitiveness in future mobility.”

Hyundai and Kia will also employ the virtual development processes into manufacturing, and product planning and design.

Initially, virtual models will be created from data collected from an architecture-based R&D system, evaluating market demand. The model is then verified using VR, allowing for the creation of a more accurate and harmonized performance goals based on customer demands.

Hyundai initially used the new system during the evaluation of the HDC-6 NEPTUNE Concept Class 8 Heavy-Duty Truck, which debuted in October at the North American Commercial Vehicle Show.

Kia, meanwhile, also plans on expanding the design evaluation system of the technology for future model developments.

Hyundai and Kia also plan to develop remote VR design assessment capabilities, which will allow for real-time virtual collaboration between design centers. The automotive makers will also implement Augmented Reality technology (AR), enhancing the virtual development process.